As their name suggests, hydrogels begin in liquid form as monomers. This viscous liquid, which can be made of synthetic or natural materials from polyester to sodium alginate, can be used as ink for 3D printing. The ink is first loaded into a syringe, then pumped through the needle as a thin filament and solidified following 3D printing to form a multidimensional structure, in the same way that Jell-O is mixed up first as a liquid before turning into a soft, bendable dessert. When hydrogels are placed in the right environment, the monomers in the liquid crosslink to form polymers, which gives shape to the hydrogel and lets it trap water.

As their name suggests, hydrogels begin in liquid form as monomers. This viscous liquid, which can be made of synthetic or natural materials from polyester to sodium alginate, can be used as ink for 3D printing. The ink is first loaded into a syringe, then pumped through the needle as a thin filament and solidified following 3D printing to form a multidimensional structure, in the same way that Jell-O is mixed up first as a liquid before turning into a soft, bendable dessert. When hydrogels are placed in the right environment, the monomers in the liquid crosslink to form polymers, which gives shape to the hydrogel and lets it trap water.

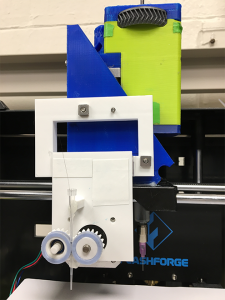

You might imagine that these supple materials are also delicate—and that’s one drawback of working with hydrogels for robotic applications. To solve this problem and allow hydrogels to be used in a greater variety of tasks and harsh environments, researchers from Carnegie Mellon University–Wenhuan Sun, a PhD student in mechanical engineering, co-advised by McGowan Institute for Regenerative Medicine affiliated faculty members Victoria Webster-Wood, PhD, and Adam Feinberg, PhD–designed a continuous fiber extruder, a device that reinforces the hydrogels, so they don’t easily break apart or lose their shape when loaded. Dr. Feinberg, a professor of biomedical engineering and materials science and engineering, previously created the 3D printer that the fiber extruders were first tested on.

Embedding fibers into hydrogels during the printing process reinforces their mechanical properties so they’re not as fragile. Creating an open-source, commercially available fiber extruder will benefit future research with hydrogels. Not only is the team’s extruder design relatively cheap at about $53, but it’s also compatible with many at-home 3D printing devices and has been tested successfully in hydrogels embedded with both synthetic and natural fibers, including silk and collagen. The team’s paper, published in HardwareX, serves almost as a formula for other researchers who want to experiment with fiber embedded hydrogel 3D printing.

“This paper describes the entire process of how we built the fiber print hub so that other people can just reference our work and then build their own without additional instruction,” Mr. Sun says of how their research serves the robotics community.

When hydrogels maintain their structural integrity, they can be applied to a wider variety of situations. Their unique attributes like flexibility and softness make them ideal tools for drug delivery and tissue engineering, but physical sturdiness opens the door to broader tasks in soft robotics. Since the continuous fiber extruders work well with natural materials like collagen and alginate, reinforced hydrogels are poised to become an adaptable material for soft robots, and they are an environmentally friendly one, too.

“We’re really interested in how we can use biodegradable materials in robots,” says Dr. Webster-Wood, an assistant professor of mechanical engineering who founded the Biohybrid and Organic Robotics Group. “These plant-based hydrogels are a really interesting direction, because we can basically farm the materials for the robots and make them renewable.”

Illustration: 3D printing devices are crucial for enabling the fiber extruder to reinforce the hydrogel. Biohybrid and Organic Robotics Group, Carnegie Mellon University.

Read more…

Carnegie Mellon University College of Engineering News Release

Abstract (Continuous fiber extruder for desktop 3D printers toward long fiber embedded hydrogel 3D printing. Wenhuan Sun, Adam Feinberg, Victoria Webster-Wood. HardwareX, Volume 11, April 2022, e00297.)